Mobile Data Collector (MDC)

Data collector application software platform developed by Antra ID brings an „easy-to-customize” data collector system that can process, edit, and transmit data captured from different Auto-ID sources.

MDC supports system integration and digitalization of multiple inventories, material handling (a receipt of goods, goods-in, delivery…), and production processes, which enables the system to realize different Process Controls and Management.

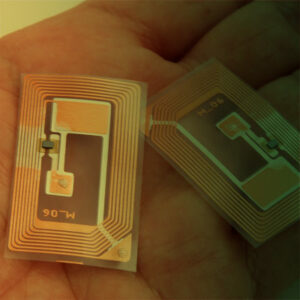

The „easy-to-customize” data collector system can process, edit, and transmit data captured from different sources. As far as its o, the operation is concerned, the MDC capturing can capture barcode and RFID „batcha” based data without a Wi-Fi connection. Thus, it can efficiently operate in areas without proper Wi-Fi coverage.

Customer optimization and scalability first

With its fully scalable feature easy to implement into ERP systems (SAP, Oracle, Microsoft Dynamics etc.). Close to production and warehouse inventory and process management enhancement by programmed MDC module implemented directly to ERP system. This saves money and time since reprogramming or implementing new additional ERP modules puts an extra burden on companies.

MDC is the best solution, even for small and medium businesses that do not run ERP systems. MDC can be implemented and used as a stand-alone solution for inventory and process control.